Optimal quality controls with the Solibri API

In today's digital world, we are no longer surprised that different applications and computer programs seem to communicate effortlessly with each other via APIs. But what exactly is an API and what does a good API give you? In this blog we take a closer look at this and we talk more about one API in particular: the Solibri API.

What are API's?

There are many software programs and online platforms available in the construction world that provide support for the digital construction process. Each program has its own qualities and benefits, where a total solution is often not available. An example of this is Solibri. This program is primarily focused on performing quality and coordination checks on various BIM models. The exchange and communication of the resulting issues is often done via an online platform, such as BIMSync, Trimble Connect or Dalux. In order for these platforms to communicate with each other, a so-called API is used. The term API stands for "Application Programming Interface.

What exactly an API is and does can be explained concretely by making a comparison with a plug and a socket. A socket can be seen as the system or the software. The plug, in this case, is the API. If the plug fits into the socket, then they can communicate with each other. However, globally there are different types of sockets, so the plug and socket do not always match. The documentation of an API tells you on which sockets the plug fits.

Solibri API

Solibri already uses the API of other platforms, but in addition has made its own API available. With this API, users can develop their own components that contribute to the effectiveness of the program. Think of custom made rules, the creation of views and additional settings.

In order to be able to check more effectively in Solibri, Based has developed a number of checking rules by using the Solibri API. One of these checking rules is based on a clash matrix.

Clash matrix

An important added value of BIM is the ability to perform automatic checks for geometric conflicts between one or more models. This is also called clash detection.

The relevance of the conflicts resulting from these automatic checks depends on the stage in which the elaboration is. For example, in a Final Design stage, a conflict between the steel structure and an air duct is more relevant than a conflict between a wall finish and a furnishing object.

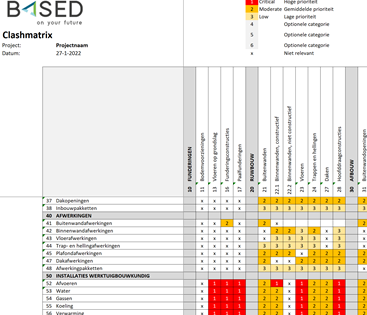

In order to reach agreement with the entire project team on the relevance and prioritization of the conflicts prior to a project phase, at Based we use a clash matrix. In this clash matrix the priority of a conflict is determined per NL/sfb code. This priority is indicated with a number from 1 to 3. The conflicts marked with priority 1 are first picked up and solved. Once these are resolved, attention will turn to the priority 2 conflicts, and so on. The clash matrix is a powerful steering tool for the entire team.

During the (design) elaboration various checks will be performed in Solibri based on this clash matrix. The standard checking rule in Solibri to gain insight into these geometric conflicts results in a list where the user must assess the relevance themselves. This takes a lot of time and is error-sensitive.

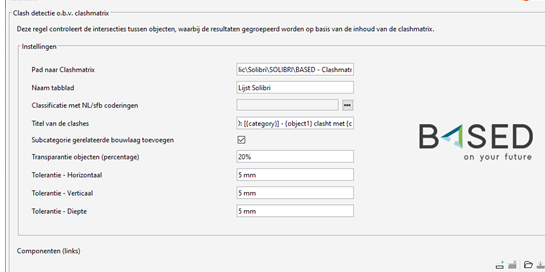

In order to facilitate this process Based has developed its own checking rule. For this purpose Based makes use of the Solibri API. This checking rule sorts the outcome of the clash detection based on the prioritization from the clash matrix.

When executing this test rule, the clash matrix is imported and its contents analyzed. Next, Solibri checks for intersections between the selected models and objects. Based on the NL/sfb codes associated with the objects in BIM, the results are categorized based on the prioritization from the clash matrix.

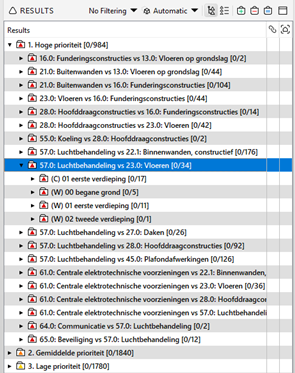

The result is a clear structure in which the conflicts are ordered by relevance and, if desired, by floor.

Check on floor impositions

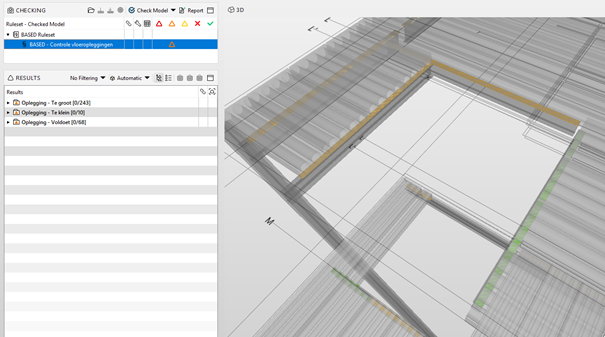

A third checking rule that Based has developed using the Solibri API is the check on the minimum and maximum floor imposition. In this checking rule, a condition can be set for the minimum and maximum imposition length of the floor elements on, for example, the steel and/or wall elements. As a result, it is possible to see at a glance which impositions do and do not meet the set conditions (imposition ok = green, imposition too large = orange, imposition too small = red).

Want to know more about the Solibri API?

With the above examples it becomes clear that the Solibri API can be used for various purposes. Are you curious about the possibilities of the Solibri API? Or do you want to know what the above applications can do for you? Please contact Arjen Rademaker (arjen@based.co.nl). He will be happy to tell you more.